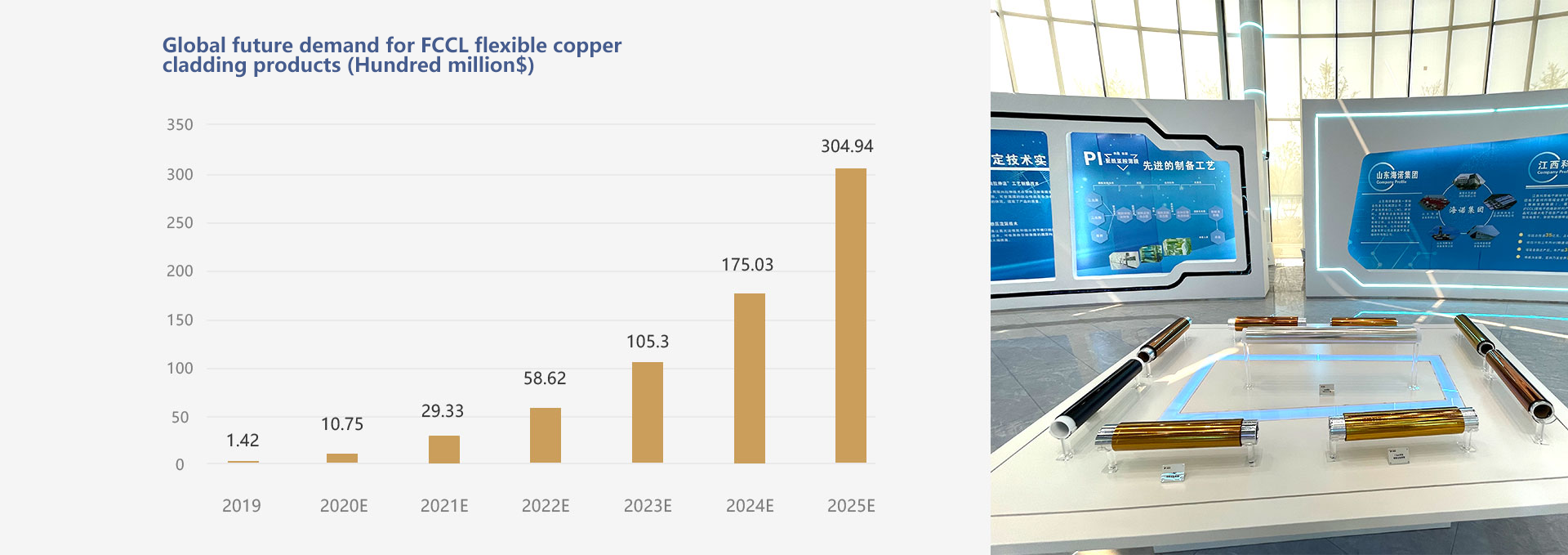

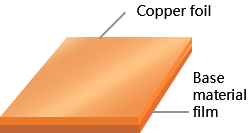

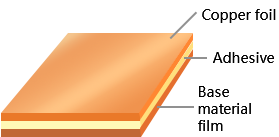

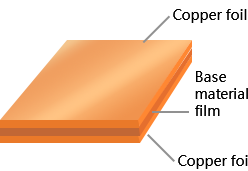

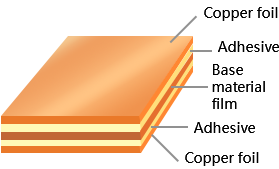

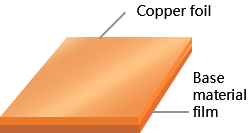

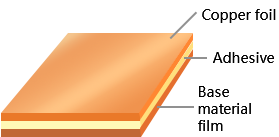

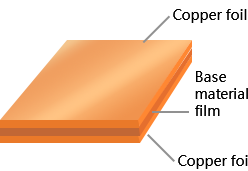

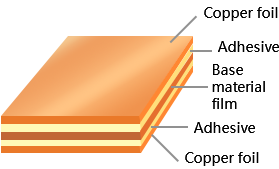

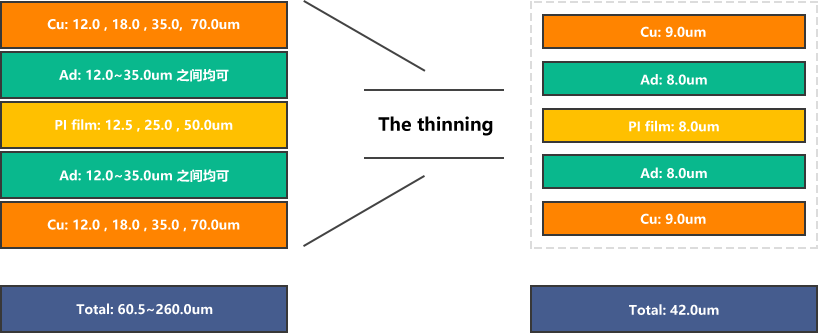

According to the difference between one covered copper foil or two covered copper foil is called single-sided copper clad plate and double-sided copper clad plate; According to the difference between the copper foil and the substrate film there is no adhesive called the laminated copper plate, no laminated copper plate.

Polyimide (PI), polyester (PET), polyethylene 2,6 naphthalene dicarboxylate (PEN:), liquid crystal polymer (LCP) and other polymer films are commonly used in the substrate film of flexible copper clad plates. Copper clad plate in the whole printed circuit board, mainly responsible for conducting, insulation and support three aspects of the function.

The performance, quality, processability, manufacturing cost and manufacturing level of printed circuit board depend on the performance of copper clad plate to a great extent.

Project unit: Q-0506TA-MB. Test method

Peel strength

Original value: KGF /cm ≧0.7 IPC-TM650 2.4.9

Tin: KGF/CM ≧0.7 IPC-TM650 2.4.9

Heat resistance of solder: PASS 288℃10sec IPC-TM650 2.4.13

Surface Resistance: Ω ≧1.0×1010 IPC-TM650 2.5.17

Volume Resistance: Ω -CM ≧1.0×1012 IPC-TM650 2.5.17

Dielectric constant: -3.5

Dielectric dissipation factor: -0.026 ASTM D150

Resin fluidity: μm 80~120 Thinflex

Dimensional stability

Machine production direction: % -0.2~0.2 IPC-TM-650 2.2.4

Horizontal production direction: % -0.2~0.2 IPC-TM-650 2.2.4

Thickness: % ±10% Thinflex UL

Fire resistance rating: -94V-0 UL

E Coverlay’s compression conditions are as follows:

A) Pressure transmission conditions:

1. Temperature: 170±10°C

2. Pressure: 30±5 kg/cm2

3. Time: ≥60min, at holding Time

B) Fast pressure conditions:

1. Prepressure temperature/time/pressure: 180±10°C / 10 seconds / 0kg/cm2

2 pressing temperature/time/pressure: 180±10°C / 120 seconds / 100±20kg/cm2

3. Baking conditions: 160°C / 60-120 minutes

THINFLEX-Q2 is kept at 4 ± 2˚C and 50 ± 20% relative humidity for up to 3 months from the date of manufacture.

Return temperature parameters:

Time: at least return to the temperature for 2 hours

Temperature: 20 ± 10℃

Humidity: 50 ± 20%

Project unit: Q-0506TA-MB. Test method

Peel strength

Original value: KGF /cm ≧0.7 IPC-TM650 2.4.9

Tin: KGF/CM ≧0.7 IPC-TM650 2.4.9

Heat resistance of solder: PASS 288℃10sec IPC-TM650 2.4.13

Surface Resistance: Ω ≧1.0×1010 IPC-TM650 2.5.17

Volume Resistance: Ω -CM ≧1.0×1012 IPC-TM650 2.5.17

Dielectric constant: -3.5

Dielectric dissipation factor: -0.026 ASTM D150

Resin fluidity: μm 80~120 Thinflex

Dimensional stability

Machine production direction: % -0.2~0.2 IPC-TM-650 2.2.4

Horizontal production direction: % -0.2~0.2 IPC-TM-650 2.2.4

Thickness: % ±10% Thinflex UL

Fire resistance rating: -94V-0 UL

E Coverlay’s compression conditions are as follows:

A) Pressure transmission conditions:

1. Temperature: 170±10°C

2. Pressure: 30±5 kg/cm2

3. Time: ≥60min, at holding Time

B) Fast pressure conditions:

1. Prepressure temperature/time/pressure: 180±10°C / 10 seconds / 0kg/cm2

2 pressing temperature/time/pressure: 180±10°C / 120 seconds / 100±20kg/cm2

3. Baking conditions: 160°C / 60-120 minutes

THINFLEX-Q2 is kept at 4 ± 2˚C and 50 ± 20% relative humidity for up to 3 months from the date of manufacture.

Return temperature parameters:

Time: at least return to the temperature for 2 hours

Temperature: 20 ± 10℃

Humidity: 50 ± 20%